아주 오래된 몸짓

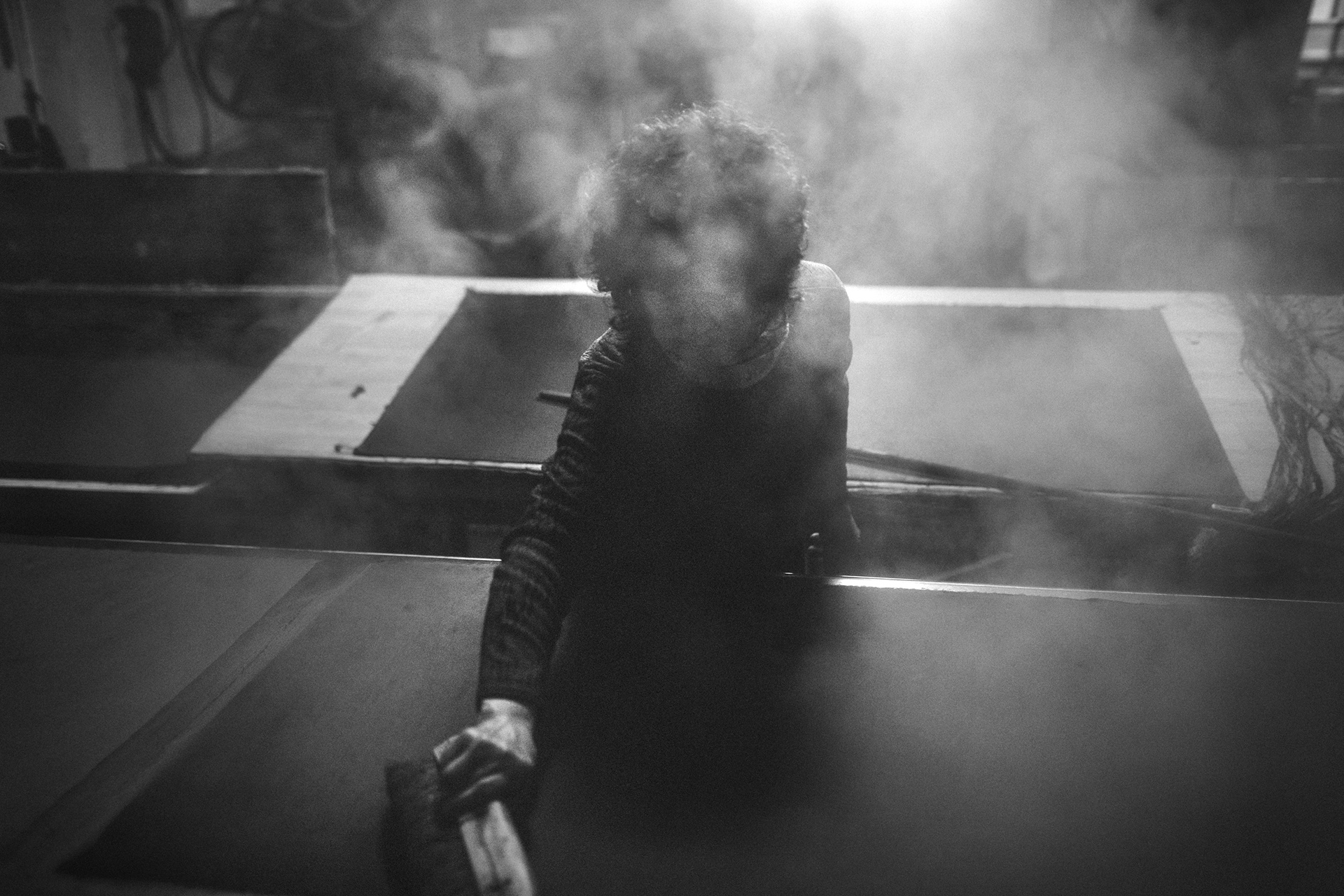

불, 물, 흙, 나무, 햇빛... 이 원초적인 것들로부터 종이가 만들어졌다. 물론 여기에 인간의 몸짓이 더해져야 한다.

2000년 전 처음 종이를 만들던 그 몸짓은 지금까지 변하지 않았다. 문명과 역사의 뿌리를 만들었을 그것은 경이롭게도 고스란히 살아남았다. 종이가 만들어지는 과정을 보는 것은 자연으로부터 역사 문명이 어떻게 시작되었는지를 상상하는 일이었다.

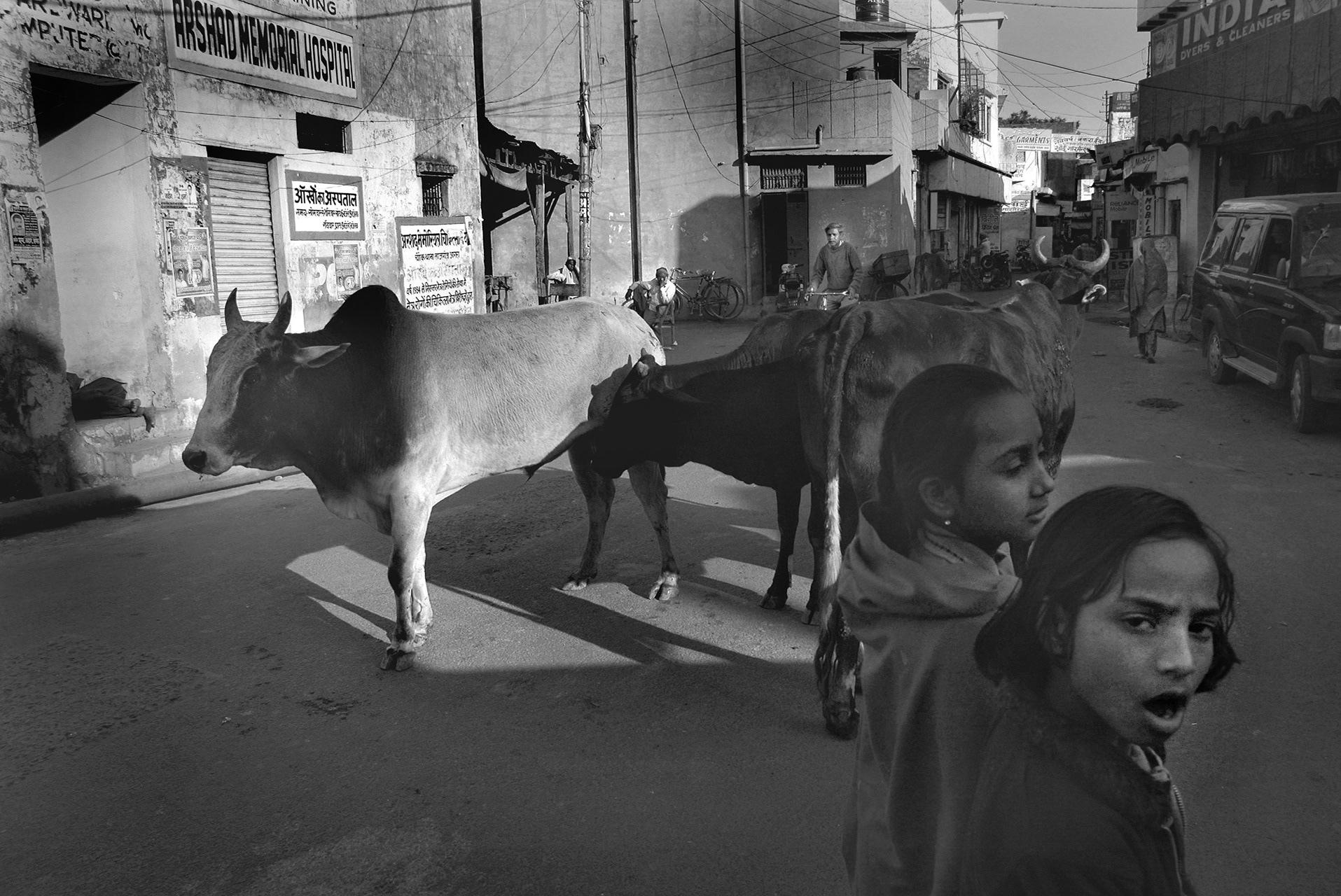

종이로부터 자연을 보고 싶었다. 종이로부터 인간을 보고 싶었다. 종이로부터 문명의 처음을 상상해보고 싶었고, 종이로부터 시간에 대해 생각하고 싶었다. 그리고 어쩌면 아주 오래된 그 몸짓에서 불변을 보고 싶었는지도 모르겠다.

A very old body movement

Fire, water, earth, wood, sunlight... From these primordial elements, paper was created. Of course, human movement should be added to this.

The body movement that created paper 2000 years ago hasn't changed since. The movement that created the roots of civilization and history has remarkably survived. To watch the process of paper making was to imagine how historical civilizations began from nature.

I wanted to see nature in the paper, I wanted to see humans in the paper, I wanted to imagine the beginning of civilization in the paper, I wanted to think about time in the paper, and maybe I wanted to see constancy in a body movement so ancient.

Fire, water, earth, wood, sunlight... From these primordial elements, paper was created. Of course, human movement should be added to this.

The body movement that created paper 2000 years ago hasn't changed since. The movement that created the roots of civilization and history has remarkably survived. To watch the process of paper making was to imagine how historical civilizations began from nature.

I wanted to see nature in the paper, I wanted to see humans in the paper, I wanted to imagine the beginning of civilization in the paper, I wanted to think about time in the paper, and maybe I wanted to see constancy in a body movement so ancient.

백지(白紙) 그리고 한지장들

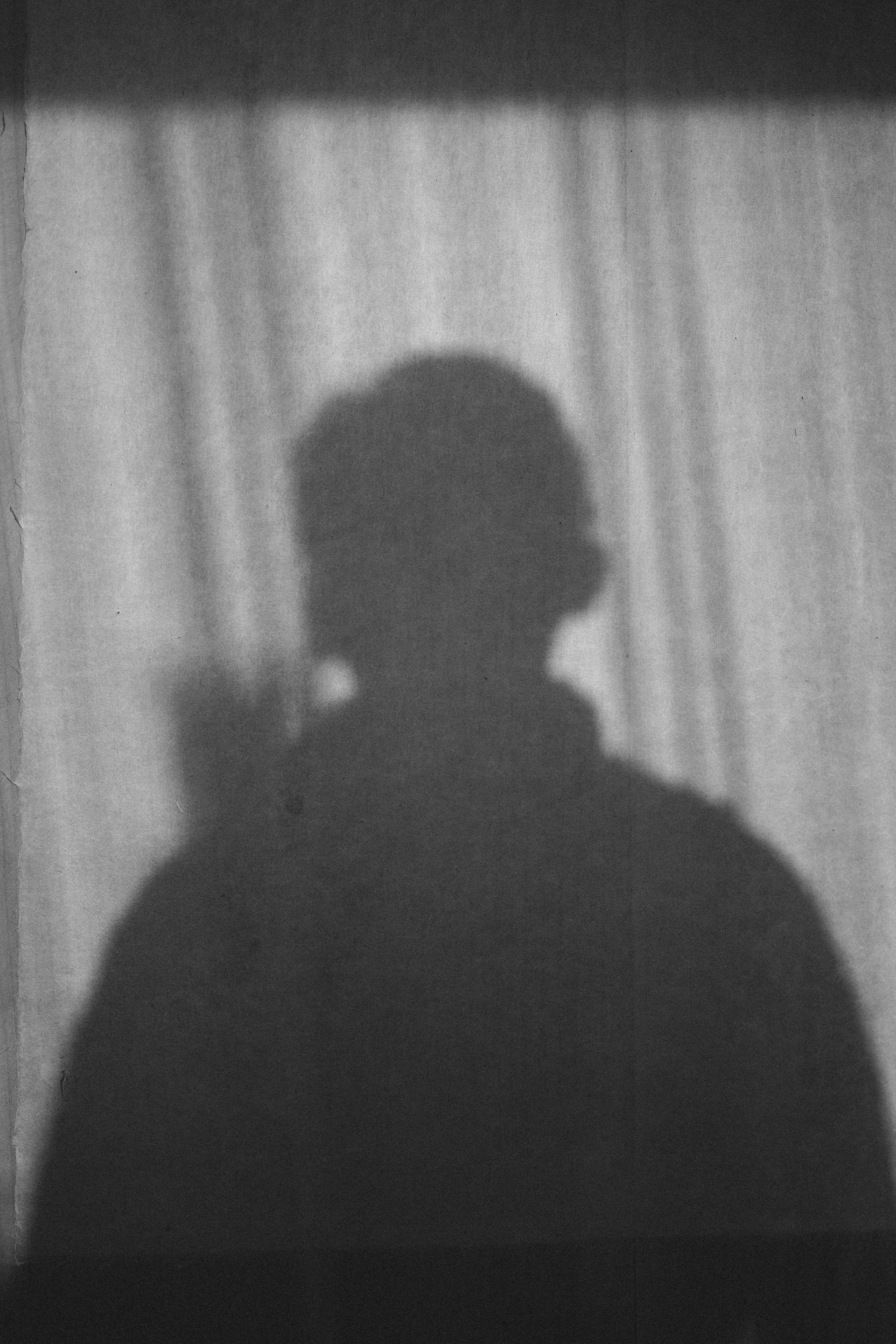

혼과 생을 바쳐 무엇인가를 만들어내려는 이들에게서 느껴지는 힘이 있다. 고집과 집념, 자부심이 만들어낸 힘이다. 그러나 거기엔 짙은 그림자도 있다. 고된 삶으로 뭉친 그림자는 그 ‘힘’을 밀다 세우기를 반복한다.

한지는 아슬아슬한 경계 위에 있다. 위대함과 소멸의 사이에서 그들은 어떤 하루를 보내고 있을까. 선 위의 인간은 어떤 존재일까.

전국의 한지 만드는 19곳을 다니며 지장(紙匠)들을 만났다.

Hanji Makers

There is a power in those who put their heart and soul into creating something. It is the power of stubbornness, persistence, and pride. But there is also a dark shadow. The shadow of a hard life pushes and pulls the 'power' back and forth.

Hanji teeter on a thin line. What kind of day do they spend between greatness and destruction, and what is it like to be a human being on the line?

I traveled to 19 hanji makers across the country and met with the makers.

There is a power in those who put their heart and soul into creating something. It is the power of stubbornness, persistence, and pride. But there is also a dark shadow. The shadow of a hard life pushes and pulls the 'power' back and forth.

Hanji teeter on a thin line. What kind of day do they spend between greatness and destruction, and what is it like to be a human being on the line?

I traveled to 19 hanji makers across the country and met with the makers.

한지는?

한지(韓紙)는 한국의 전통 종이다. 아흔 아홉 번의 손길로 만들어진다고 해서 백지(白紙)라고도 부른다. 그만큼 생산 과정이 복잡하고 지난하며 땀과 정성이 들어가야 만들어지는 종이다.

겨울에 벤 1년생 닥나무를 쪄서(닥무지) 껍질을 벗기고 말린 뒤 잿물에 삶는다(증해). 이를 볕 드는 물에 며칠 담갔다가 티를 고르고 방망이로 내려쳐(고해) 짧은 섬유질로 만든다. 이후 황촉규 뿌리로 만든 닥풀과 함께 큰 물통에 넣고 섞은(해리) 뒤 대나무발로 떠서(초지) 말리고 펴면(도침) 한지가 된다. 물론 이 과정에는 매우 까다로운 원료 조건과 수많은 세부 공정, 부차적인 작업이 추가된다.

‘비단이 오백년, 한지가 천년 간다’는 말은 한지의 뛰어난 보존성을 상징한다. 8세기에 제작된 무구정광대다라니경(751년 제작)과 신라백지묵서 대방광불화엄경(754~755 제작)은 모두 1300여년의 시간이 흘렀지만 고스란하다. 프랑스의 루브르 박물관과 이탈리아의 국립기록유산보존연구소(ICRCPAL)가 미술품 복원용지로 ‘외발뜨기’로 상징되는 한국의 전통 한지를 선택했다는 뉴스는 우연이 아니다.

그러나 오늘날 한지 업계는 위태롭다. 2010년대에 접어들면서 소비가 급감했고 만드는 곳 역시 크게 줄었다. 게다가 값싼 중국산 한지의 수입으로 가격경쟁력도 잃어 현재 한국의 전통 공방은 스무 곳이 채 되지 않는다. 이마저도 대부분 영세하고 일부는 휴업 중이다. 작업자의 연령대가 높지만 후계자를 둔 곳은 몇 곳 되지 않는다. 중국의 선지나 일본의 화지처럼 국가주도의 산업화 기회도 없었다.

What is Hanji?

Hanji (韓紙) is a traditional Korean paper. It's also known as 'Hundred paper' because it's made with ninety-nine course. The production process is complex and lengthy, and it takes a lot of sweat and labor to make.

The first year-old paper mulberry cut down in winter are steamed, peeled, dried, and boiled in lye. It is soaked in sunlight for a few days, then picked and beaten with a bat to make short fibers. It is then mixed in a large vat of water with dak grass made from the roots of huangchok beef, scooped out with a bamboo foot, dried, and stretched to make hanji. Of course, this process requires extremely demanding raw material conditions and a myriad of detailed processes and secondary operations.

Hanji (韓紙) is a traditional Korean paper. It's also known as 'Hundred paper' because it's made with ninety-nine course. The production process is complex and lengthy, and it takes a lot of sweat and labor to make.

The first year-old paper mulberry cut down in winter are steamed, peeled, dried, and boiled in lye. It is soaked in sunlight for a few days, then picked and beaten with a bat to make short fibers. It is then mixed in a large vat of water with dak grass made from the roots of huangchok beef, scooped out with a bamboo foot, dried, and stretched to make hanji. Of course, this process requires extremely demanding raw material conditions and a myriad of detailed processes and secondary operations.

The saying, "Silk lasts five hundred years, Hanji lasts a thousand years" symbolizes Hanji's excellent preservation. The Mugujeong Gwangdae Darani Sutra (751), the Silla Baekji Mukseo, and the Daebanggwang Bulhwaeum Sutra (754-755), all dating from the 8th century, are still intact after more than 1,300 years. It's no coincidence that the Louvre in France and Italy's National Institute for the Restoration and Preservation of Archival Heritage (ICRCPAL) have chosen traditional Korean hanji, symbolized by the "dark-bright(Multidirectional weaving)," to restore artworks.

Today, however, the industry is in a precarious position. Consumption has plummeted since the 2010s, and the number of places where it is made has shrunk significantly. In addition, the import of cheap Chinese paper has made it uncompetitive, and there are now fewer than two dozen traditional Korean workshops. Most of them are small. Many of the workers are older, but few have successors. There was no opportunity for state-led industrialization like China's Sunji or Japan's Washi.

Today, however, the industry is in a precarious position. Consumption has plummeted since the 2010s, and the number of places where it is made has shrunk significantly. In addition, the import of cheap Chinese paper has made it uncompetitive, and there are now fewer than two dozen traditional Korean workshops. Most of them are small. Many of the workers are older, but few have successors. There was no opportunity for state-led industrialization like China's Sunji or Japan's Washi.